Aluminum cans have become an integral part of our daily lives, offering convenience and sustainability. Have you ever wondered how these ubiquitous beverage containers are made? In this blog post, we will explore the fascinating production process of aluminum cans and highlight its efficiency and environmental benefits.

Aluminum Coil Preparation:

The production of aluminum cans starts with the preparation of aluminum coils. These coils, typically measuring 1.5 meters in width and weighing around 9 tons, serve as the primary material for can manufacturing. Aluminum coils undergo thorough quality checks to ensure they meet the required specifications.

Coil Shearing:

To facilitate the production of millions of aluminum cans, the large coils are sheared into smaller, more manageable sheets. These sheets are precisely cut according to the desired width, considering the size of the cans to be manufactured.

Blank Cutting:

The sheared aluminum sheets are further processed in blank-cutting machinery. This equipment precisely cuts the sheets into individual flat blanks, which will form the body and ends of the cans. The blank-cutting process ensures uniformity and accuracy in can size.

Cupping:

The cut aluminum blanks are then fed into cupping machines, where they undergo a series of operations to transform them into the characteristic cylindrical shape of a can. The blanks are pushed into a die, which stretches and molds them into the cup-like shape of the can's body.

Drawing and Ironing:

Next, the cup-shaped blanks go through a process called drawing and ironing. This process involves compressing the cup between a series of dies, simultaneously stretching the aluminum material and reducing its diameter. This step strengthens the can and achieves the desired height.

Trimming and Cleaning:

After the can bodies are formed, excess aluminum at the open end is trimmed off to create a smooth finish. The cans then undergo a thorough cleaning process to remove any contaminants and ensure their hygiene.

End Production:

Simultaneously, the can ends are manufactured separately. The aluminum blanks for the can tops are cut, formed, and shaped using specialized machinery. They undergo a similar trimming and cleaning process to ensure they meet quality standards.

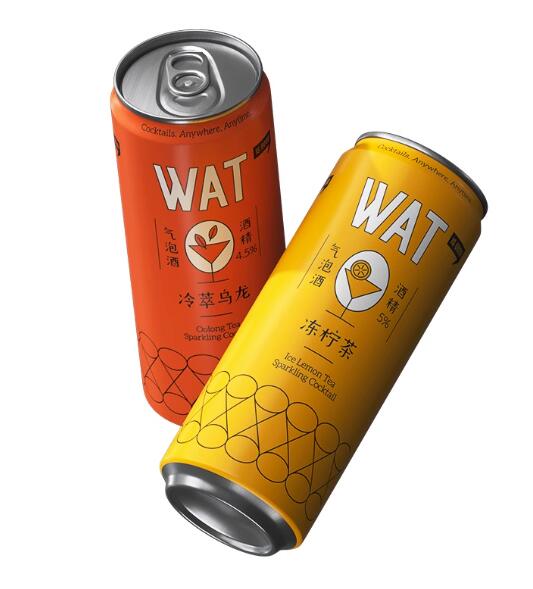

Coating and Decoration:

To enhance the visual appeal of aluminum cans and protect them from corrosion, a thin polymer coating is applied to both the can bodies and ends. This coating provides a barrier between the aluminum material and the beverage inside.

Assembly and Packaging:

In the final stage, the coated can bodies and ends are assembled, sealed, and checked for proper functionality. The cans are then packaged into bundles or cases, ready for distribution and filling with various beverages.

The production process of aluminum cans exemplifies efficiency and sustainability in modern manufacturing. From the preparation of large aluminum coils to the precise molding and assembly of individual cans, each step is optimized to meet the demand for millions of units. Furthermore, the lightweight nature of aluminum cans contributes to reduced transportation costs and lower carbon emissions. As we strive for a greener future, aluminum cans will continue to play a crucial role in packaging innovation and sustainable development.